- Home

- Company

- service

- Products

- Desing & Consulting

- Applications

- Repairs & Retrofits

- Contact Us

Mobile

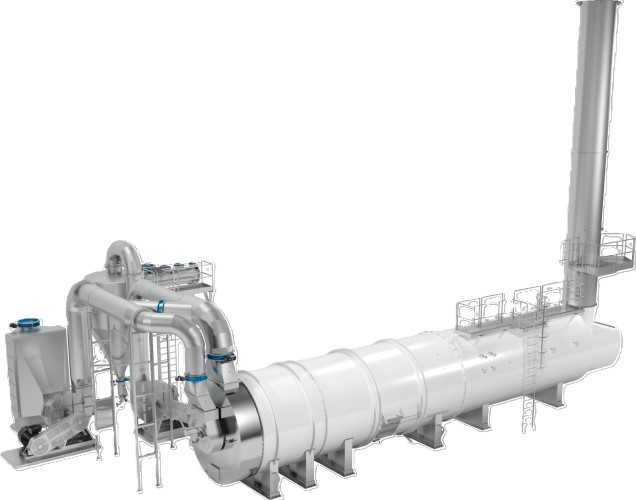

Pollutants like volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) are emission concerns that need abatement before releasing process exhaust into the atmosphere. A popular treatment method for these compounds is a thermal oxidizer. A thermal oxidizer heats the VOCs or HAPs to a precise temperature until they are oxidized. The oxidation process breaks down the harmful contaminants into carbon dioxide and water. Thermal oxidizers are ideal in applications where particulates may be present and where there is a higher concentration of VOCs.

UNEOTEC thermal oxidizers are effective with a greater than 99% destructive rate. Integrating a heat exchanger, however, modifies the process to recuperate the heat that is released so that it is reused within the system to reduce operating costs and increase efficiency. Designing the right system for your configuration is key to a long-lasting, reliable solution.

Capacity: Min : 250 Nm3/Hr to 50000 Nm3/hr

Applications : Packed Bed scrubbers,

Fume Scrubbers,

Sox scrubber,

Chromes scrubbers,

Nox scrubbers,

Mercury scrubber,

Incinerator scrubber,

Acid fume scrubber,Industrial Odor scrubber

General water scrubber

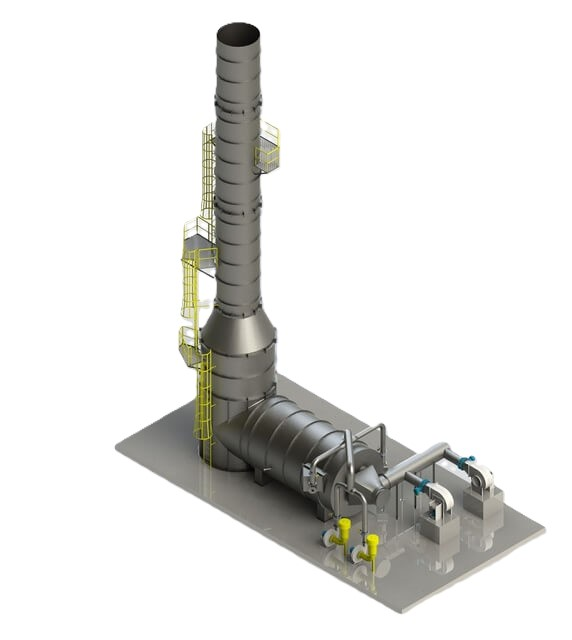

A Direct Fired Thermal Oxidizer (DFTO), or non-recuperative thermal oxidizer, is very basic in design, with the main components consisting of a burner and a combustion (retention) chamber. Commonly referred to as afterburners, incinerators, or direct fired thermal oxidizers, our Thermal Oxidizer routinely exceeds all regulatory requirements.

Non-recuperative thermal oxidizers are used on applications where primary air to air heat exchangers are not necessary. Special applications that have very high solvent concentration levels, low air volumes, high energy demand or secondary heat recovery needs, among others can benefit from our UNEOTEC-Thermal Oxidizers.

• Process gas volume ranging from 500 SCFM to 30,000 SCFM

• VOC concentrations ranging from 10% to 25% of the LEL

• Presence of particulate in the process gas or after combustion of the VOC

• Process gas temperatures up to 600° F

• This technology does have some aspects that warrant consideration, including what is typically a higher operating cost, as well as higher NOx emissions than those produced using a recuperative catalytic oxidizer or a regenerative thermal oxidizer. It is a good choice for any technology process that has a high continuous VOC stream, a small air flow rate, or batch type cycling. Also, a secondary system added to a recuperative oxidizer can raise efficiencies and reduce operational costs. Operation schedules should also be considered with recuperative thermal oxidizers, as the stainless-steel alloys utilized in the heat exchangers do have finite life spans if the system is going to be turned on and off each day.

UNEOTEC thermal oxidizers are effective with a greater than 99% destructive rate. Integrating a heat exchanger, however, modifies the process to recuperate the heat that is released so that it is reused within the system to reduce operating costs and increase efficiency. Designing the right system for your configuration is key to a long-lasting, reliable solution.

Mobile