- Home

- Company

- service

- Products

- Desing & Consulting

- Applications

- Repairs & Retrofits

- Contact Us

Mobile

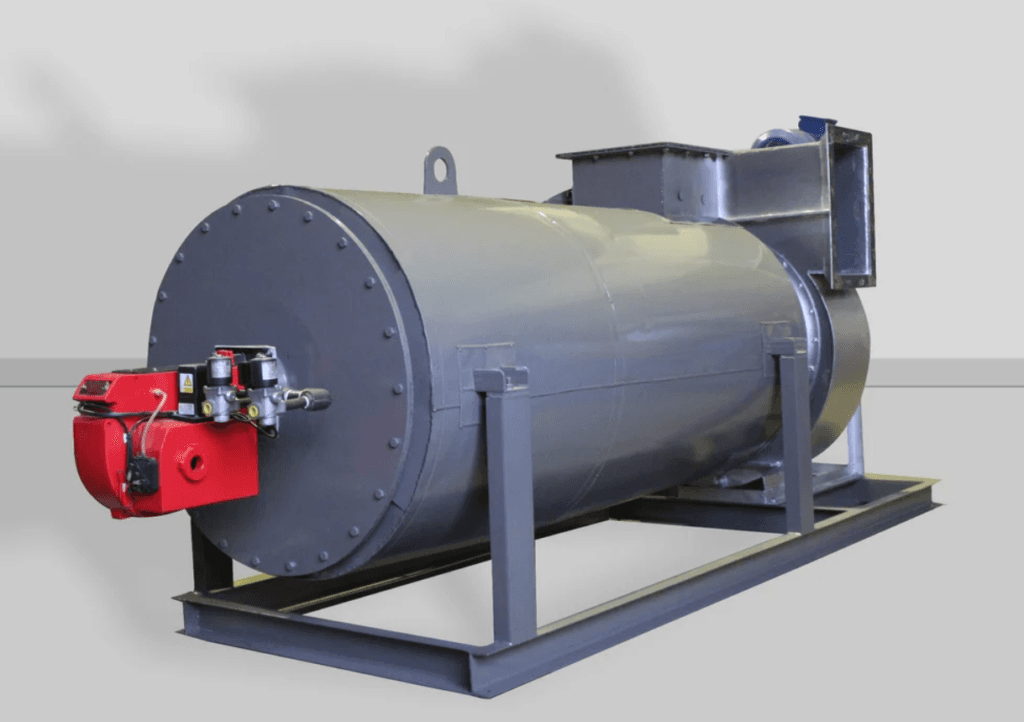

A hot air generator is a heating device usually used in industrial applications. Its basic function is to produce hot air by heating air and directing this hot air into a space or process. Hot air generators are used in warming, drying, heating and other applications in many different industrial processes.

Hot air generators are available in various sizes and capacities. These generators can be designed to suit different industrial requirements. Which type of hot air generator to use can vary depending on the process needs and energy source. There are generators that provide direct and indirect heating.

Hot air generators produce hot air using a fuel or energy source with high efficiency. They can reach the required temperature quickly, so they are useful in industrial applications that require fast processing. Indirect heating generators help control

Capacity: 0.5 Mkcal /hr to 50 Mkcal/hr

Temp : 110 Deg C to 1000 Deg C

FUEL BASED, Oil, Gases, Coal/ Pet coke, Bio mass / Agro waste, Waste liquids & Gases

material: Mineral material drying, Flash dryers, Rotary dryers, Fluidized beds, Food grade powders

Uneo Hot air Gen

Uneo Hot air Gen

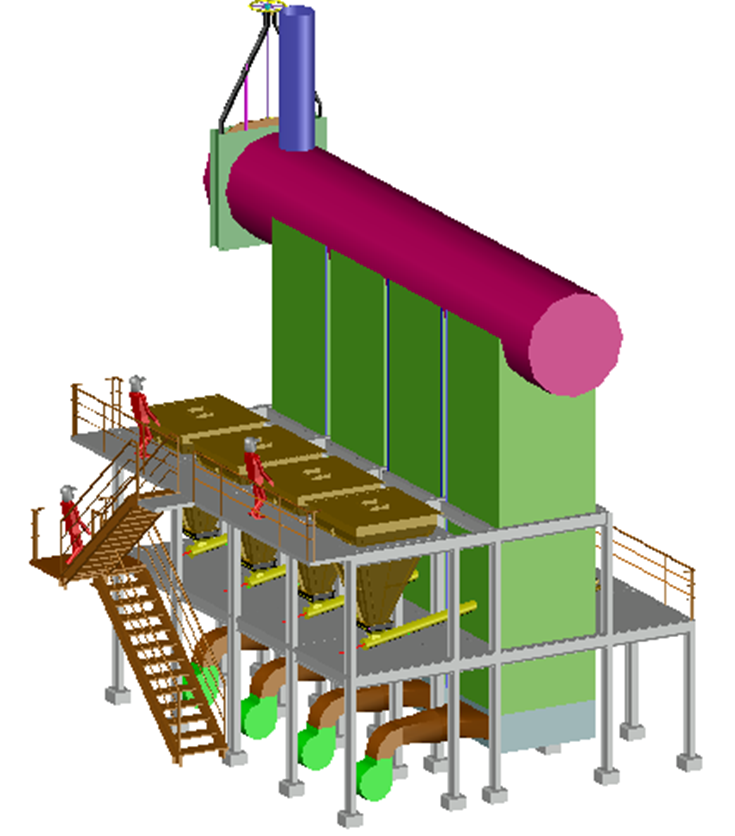

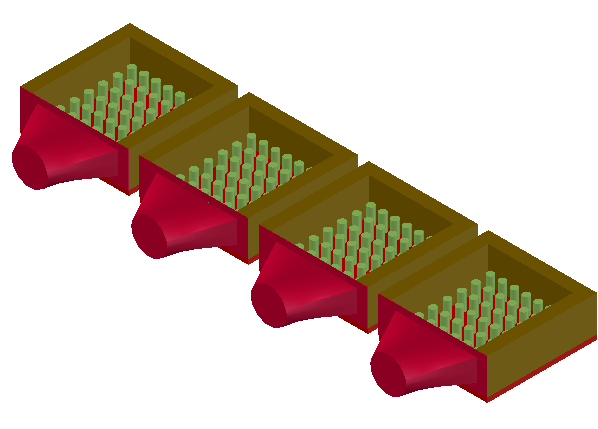

Technology in Bubbling Beds, Fuels combined with inert materials, such sand or ash, or special media are burned inside a fluidized bed. Air is introduced into the bed at a precise velocity, which causes bubbling action both above and below the bed and causes the solid particles to mix equally and behave like a fluid. Solid fuels can burn in fluidized bed reactors with 90–95% efficiency or better, producing gas and heat at the required rate.

The fuel feeding devices, hoppers, elevator, cyclones, nozzles, ash settling chambers, ash removal mechanisms, fluidized bed furnace, fluidization air blower, pneumatic fuel feeding blower, instrumentation & control equipment, operation panel board, motors & electrical components are all part of the system.

Capacity: 5 Mkcal/hr to 40 Mkcal/hr

Material : Coal / Biomass/ Solid wastes/ Liquid wastes

Hot Air temperature@ outlet : 250°C to 800°C

Hot Gas Pressure@ Outlet : (-5) mmWC to (+) 40mmWC

• The fluidized Bed HAG system is capable of combusting several types of fuel such as coal, corncobs, wood scraps, and precipitates from waste water treatment, at high efficiency. In addition, the emission control system of toxic gases such as sulphur dioxide and oxides of nitrogen in this technology is easy to operate, inexpensive, and efficient.

• Virtually complete combustion at low excess air level.

• Increased energy recovery potential and system efficiency.

• Odor elimination.

• Minimal Maintenance.

• Lower capital costs.

• Fully Automated system, which maintain automatically all the operating parameters of the system according to fuel.

Favourable Ash Properties: The high combustion efficiency of a fluidized bed results in a reduced amount of inorganic material as fine ash. Low combustion temperatures in the fluidized bed minimize the formation of toxic materials that might carry over with the ash..

| BIOMASS / SOLID FUEL DATA | |

|---|---|

| Biomass / Solid Fuel Size | 0-6 mm |

| Moisture content | <20% |

| Ash content | up-to 30% |

| APPLICABLE FUELS | |

| Wood Wastes (Bar, Chips, Saw Dust etc.) | |

| Agriculture wastes (Husks, Ground nut shell, Cotton Stack etc.,) | |

| Lignite / Coal / Solid waste | |

| Hazardous Fuels/ Waste Oils/ High Viscous wastes/ Bio Waste |

Mobile