- Home

- Company

- service

- Products

- Desing & Consulting

- Applications

- Repairs & Retrofits

- Contact Us

Mobile

The removal process is achieved by bringing the gas stream into contact with the scrubbing liquid, which facilitates mass transfer of the contaminants into the liquid. When the water is recirculated, addition of fresh water is necessary to purge contaminants and replace evaporation losses. Fresh water may be added to the recycle continuously or periodically.

UNEOTEC has a variety of high-efficiency wet scrubbers for the removal of inorganic gases, odors, fumes, acid fumes, sulfuric acid, chrome, NOx, fine particulate, fine dusts from industrial gas streams, mercury, HCl, Cl2, SO2, and HF.

Capacity: Min : 250 Nm3/Hr to 100000 Nm3/hr

Applications : Packed Bed scrubbers,

Fume Scrubbers,

Sox scrubber,

Chromes scrubbers,

Nox scrubbers,

Mercury scrubber,

Incinerator scrubber,

Acid fume scrubber,

Industrial Odor scrubber,

General water scrubber

Applications : Fertilizers,

Pulp & Paper,

Chemical,

Mineral,

Steel producing,

Food Process,

Pharma,

Oil& gas,

Metal Processing ,

Power & Energy

Vertical Flow:

• Gas flow is counter-current to the liquid flow.

• Smaller footprint required at the expense of increased height requirements.

• Generally, less costly from both capital and operational perspectives.

• Scrubber vessel is round (generally).

Cross flow/Horizontal Flow :

• Gas flow is cross-current (perpendicular) to the liquid flow..

• Sacrifices footprint for height.

• Slightly less efficient due to cross-current flow, although this disadvantage is minimized when treating the more water-soluble acids (e.g. H2SO4, HCl).

• Scrubber vessel is rectangular.

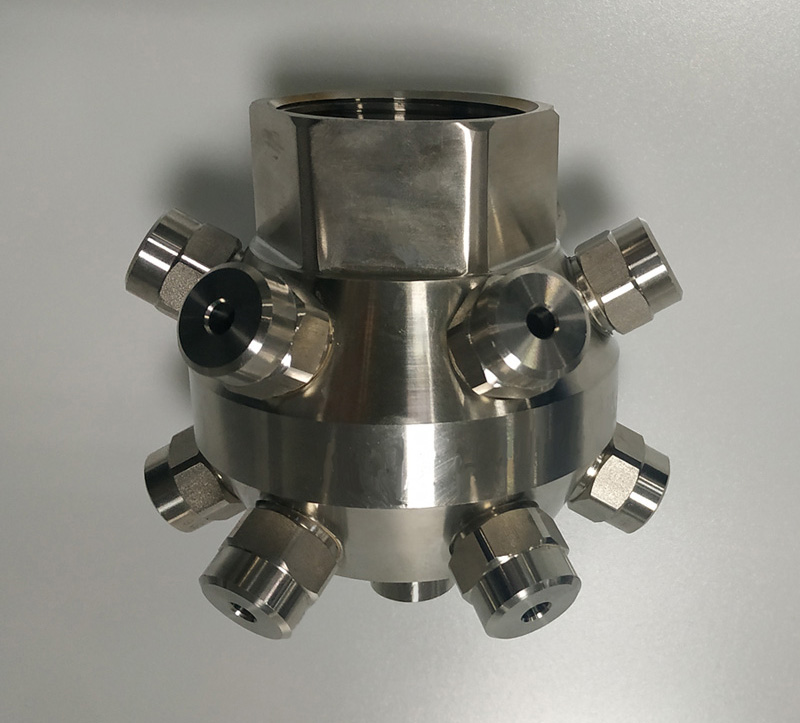

Uneotec has own R&D for Scrubber internals design and development for various range of applications and atomization of different dense liquids.

Mobile