- Home

- Company

- service

- Products

- Desing & Consulting

- Applications

- Repairs & Retrofits

- Contact Us

Mobile

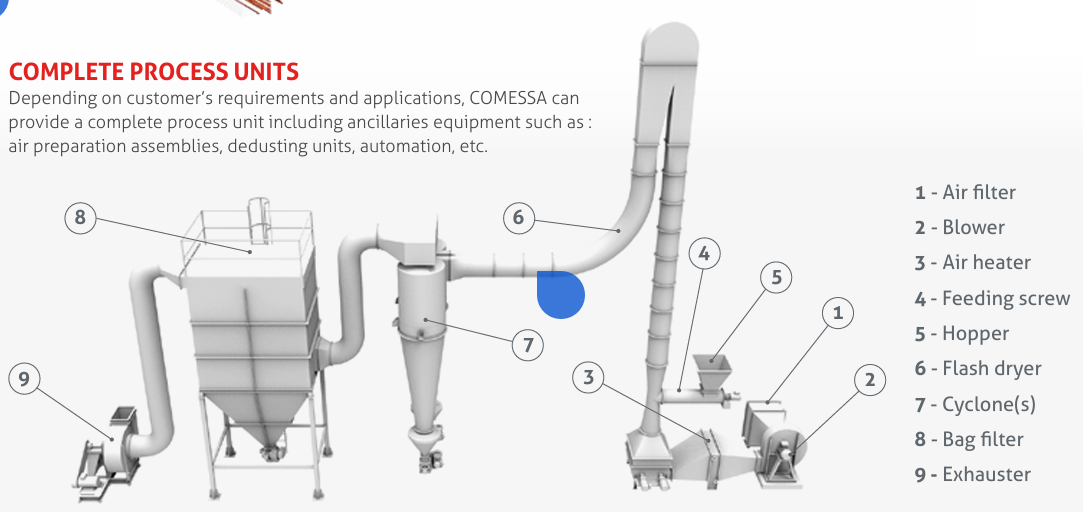

Flash drying works on the principle of pneumatic transport using hot air. Wet product is introduced into a high velocity air stream through a special Venturi feeder. Highly turbulent airflow generates an intense gas-solid thermal exchange and disaggregates the product. This allows a rapid evaporation in a few seconds residence time. Rapid drying process avoids overheating of product allowing the use of high temperature drying gases.

At dryer outlet, dried product is recovered by means of a gas-solid separator (cyclone, bag filter, etc.). Partial recycling of dried product in wet material can be considered in case of sticky product. This process is particularly suitable for fine products or filter cakes.

Capacity: Min : 2 TPH to 200 TPH

Applications : Limestone powder

Slag,

Minerals,

Chemical powders,

Food grade powders,

Agro waste (sized),

Industrial Odor scrubber,

General water scrubber

Efficient and economic drying for all Solids with effective heat transfer

Rotary Dryers are one of the widely used Dryer in process industry. Especially in fertilizer and minerals industry for drying products such as coal, clay, gypsum, kaolin, limestone, mineral sand, potash, silica sand etc.

Rotary Dryers from UNEOTEC provide controlled, uniform and efficient drying to help you achieve desired product quality. With a specialized design and sturdy construction our Rotary dryers are able to provide excellent thermal efficiency.

Rotary Dryers consist of cylindrical shell supported by riding rings to provide circular motion. These dryers come with lifter or flights on its inner circumference to lift and distribute material. These lifter also facilitates material movement towards final discharge point. Rotary dryers are always aligned on slight slope to facilitate movement of material from feeding point to discharge point under gravity.

Our stringent quality standards and detailed CFD analysis ensures a consistent and enduring performance.

The Co-current type Rotary Dryer is ideal for the materials that has tendency to stick and has high moisture content. Here Air and feed are introduced from the same direction and material comes in contact of hot air at its highest temperature, which instantly evaporates surface moisture.

The initial heat transfer rate is high, causing an immediate and considerable drop in gas temperature, which prevents overheating of the material and the dryer shell. The material which is in its final stage comes in contact of air/gas at its lowest temperature thus enabling the easy control over the moisture

• In house Design and Engineering

• In house Design and manufacturing of Hot air generator with all kind of fuels

• Effective process design

• Compact system design

• Clean environment solutions

• Long life components

Counter current type of rotary dryer is an ideal solution for materials that must be dried to contain very low level of moisture. Here warm air is introduced at the discharge point of the Dryer.

The material comes in contact with the warm air first at its lowest temperature, which goes on increasing as the material travels further.

The material which is at its final stage comes in contact of air/gas at its highest temperature thus maintaining very low level of moisture content.

Unoetec employs highly advanced methodology of Computational Fluid Dynamics (CFD) analysis, to deliver guaranteed results for your Business, Process reliability and system performance. CFD simulation helps to foresee performance before actual execution of the systems, without actual installation of the system. It also helps understand the most vital parameters for improving performance

Our capacities : 5 TPH to 150 TPH.Mobile